Titleist Launches Virtual Tour of Pro V1 Manufacturing Process

The manufacturing process for the new Titleist 2021 Pro V1 and Pro V1x golf balls is now on display for golfers around the world through the Titleist Ball Plant Virtual Tour on Titleist.com.my.

The manufacturing process for the new Titleist 2021 Pro V1 and Pro V1x golf balls is now on display for golfers around the world through the Titleist Ball Plant Virtual Tour on Titleist.com.my.

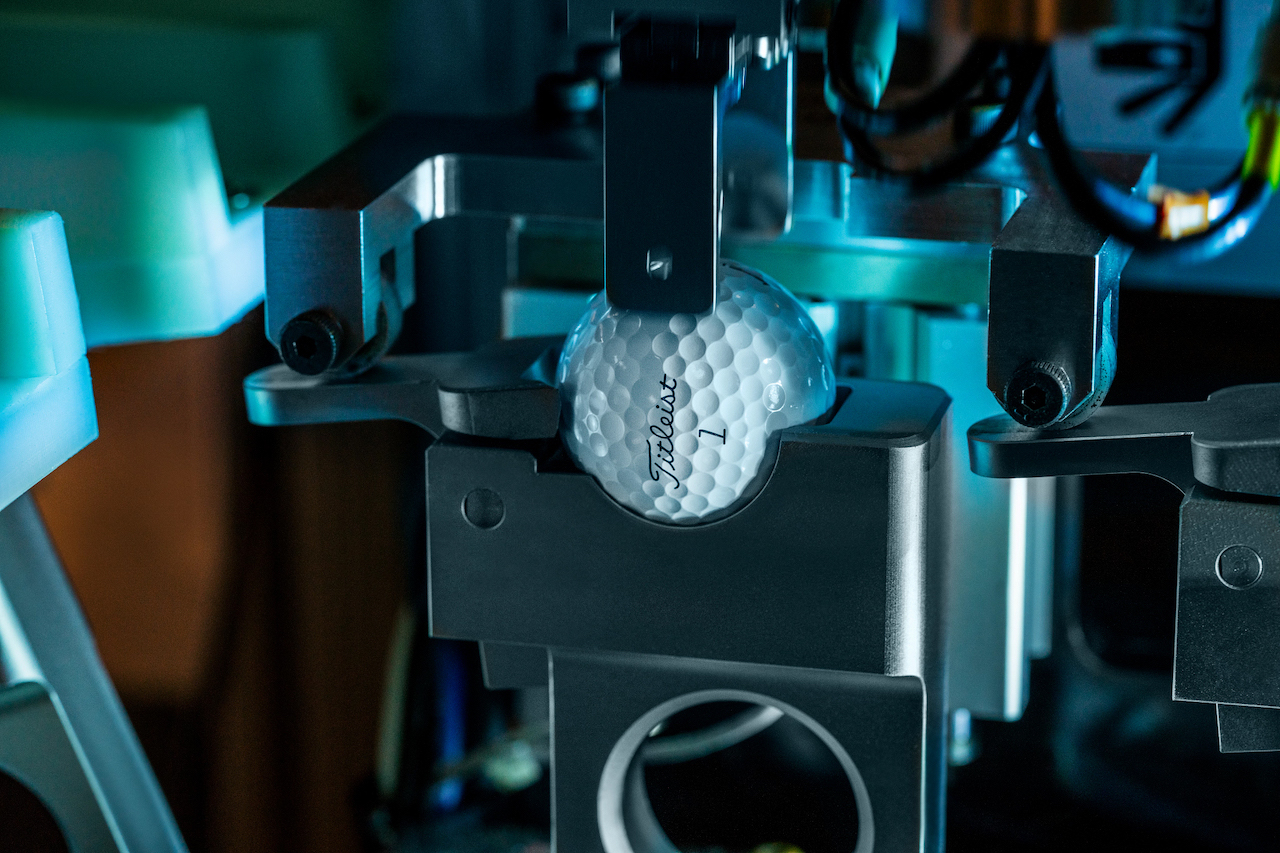

Available on mobile and desktop devices at Titleist.com.my/BP3-Virtual, the virtual tour takes golfers through every step of the manufacturing journey for Pro V1 and Pro V1x, exhibiting how each layer comes together to deliver the best performing, most consistent and highest quality golf balls in the game.

“We’re excited that golfers everywhere now have the opportunity to go behind the scenes of our process, learn how their golf ball is made from core to cover and see everything our R&D and Operations teams are doing to earn their trust on every single shot,” said Jeremy Stone, Vice President, Titleist Golf Ball Marketing.

In recent years, many of the world’s best players have experienced the manufacturing process in person, including major champions Adam Scott, Justin Thomas, Webb Simpson, Jordan Spieth and Bubba Watson:

Adam Scott: “I think the most surprising thing I took away from touring the plant is how tight the tolerance levels are in making the golf ball and how strenuous the checks are to make sure there is very little variation ball to ball. For someone whose livelihood and dreams depend on it, it’s nice to see how dedicated Titleist is to provide you with the same ball every time out of the box.”

Justin Thomas: “Seeing the process up close gave me even more confidence than I already had in my golf ball. I always trust my go-to cut shot – that’s a shot I’m very comfortable and most consistent with distance-control wise – and you see why I’m able to have so much confidence in it when you go through the plant. The process just to make one single golf ball and then see how it’s made the exact same, thousands and thousands of times more, it just was extremely impressive.”

Webb Simpson: “I had no idea how much went into the process. And it was great to meet the people who are making what you rely on week in, week out for your job. I walked away feeling even more confident knowing that at every station, every person’s job was super important to them and they were going to do it to the best of their ability.”

Jordan Spieth: “There’s a reason why Titleist has the #1 ball in golf and it has been for decades. There’s just an extra level of precision that leads to us players trusting it. It leads to the amateurs trusting their golf ball. Just knowing what goes into it on Titleist’s side only solidifies that confidence.”

Commitment to the Process

It was in the 1930s that Titleist founder Phil Young – frustrated with the inconsistent performance of the golf balls he was playing, and not being rewarded for his best swings – set out to make the best golf balls in the world. Young, an avid golfer and owner of a precision moulded rubber company, was fueled by the belief and understanding that the performance and quality of a product can only be as good as its manufacturing process – and that golfers should never have to worry how their golf ball is going to perform when they put a good swing on it.

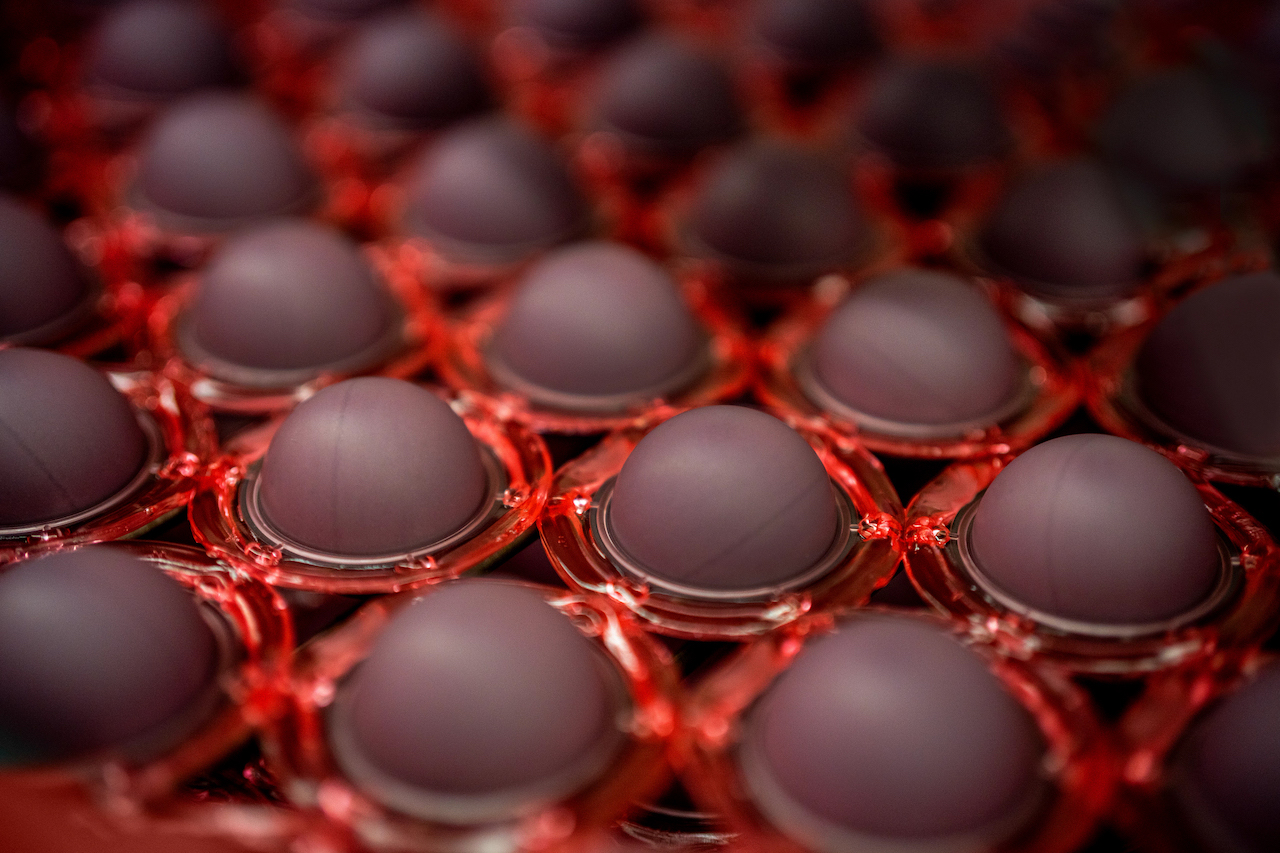

It is this enduring commitment to the process – and helping golfers shoot their lowest scores – that continually pushes Titleist’s exacting performance and quality specifications to even tighter tolerances. Even the slightest variations in golf ball construction can have dramatic performance implications, for example:

- If a golf ball core is just 4/100ths of an inch off-centre – about the thickness of a credit card – shot dispersion for every club in your bag can double.

- A golf ball with uneven dimple depths – off by as little as the width of a human hair – can turn a good swing into a bad shot and cause the ball to fly offline.

Video: Eye-Opening Aerodynamics with Rafa Cabrera Bello: Watch how microscopic inconsistencies in dimple depths affect the flight of a golf ball: https://youtu.be/aeibKavgytc.

Pro V1 and Pro V1x golf balls – the most played and best-selling golf balls around the world – are made at both Titleist Ball Plant 3 (New Bedford, Mass.) and Titleist Ball Plant 4 (Thailand). The manufacturing and quality assurance processes seen during the Virtual Tour are the exact same ones used at both facilities, ensuring that every Pro V1 and Pro V1x golf ball delivers consistent performance in every dozen – and on every shot. Every Titleist golf ball model is made by Titleist associates in Titleist owned and operated manufacturing facilities.

The Virtual Ball Plant 3 Tour is guided by Iona Stephen, host of Golf TV’s “Golfing World,” and a broadcaster for Sky Sports Golf. Stephen, who has played professionally on the Ladies European Tour, toured Titleist Ball Plant 3 in October 2019.

“I’ve always played a Titleist golf ball because I believed it was the best, but I never could have imagined the scope of the process or level of precision that goes into making each and every golf ball,” Stephen said. “The passion and the commitment of the people – many who’ve worked at BP3 for over 20 or 30 years – is something that I’ll never forget.”

Search

Other Equipment News

- Brooks Koepka Joins Srixon and Cleveland Golf Tour Staff

- Callaway’s Epic Max Fast Series Offers Max Speed and Flight Via Weight Reduction

- Titleist Introduces Innovative Pro V1 Radar Capture Technology

- The New Addition to the FJ Flex Family Have New Style Options and Great Performance

- The New FJ Traditions are Simply Classic

- Titleist Introduces New Scotty Cameron Phantom X 9.5 Triple Black Putter

- Tee Up from Home or the Driving Range with the New Garmin Approach R10

- Callaway JAWS Full Toe Wedge Designed to Give Golfers Shot Control

- Introducing the New Contour Series/Contour Casual Comfort Reigns Supreme

- New FJ Footwear for Women

- More news...